How to judge the cleanliness of workpiece in Jiangmen hardware manufacturing and processing

Qualitative comment on the method of cleanliness

① wipe method: wipe the surface of the object with dry, clean and lint free cloth (such as gauze), and judge the surface cleanliness according to the degree of dust. This method is simple but not accurate.

Water drop method & a method of evaluating cleanliness with contact angle. Under certain conditions, the larger the diameter of the water drop (a certain volume) on the surface, the smaller the contact angle, and the higher the cleanliness.

③ the present water film method is to immerse the cleaned object in the water, make the surface of the object vertical to the water surface, and pull it upward. If the water film formed by the surface of the object can occupy all the surface evenly after leaving the water surface, the clarity and cleanliness will be high. If the outer surface is visible and does not form a water film, it should be clarified that it is not clean.

(4) spray spray the uniform droplet droplets onto the dry surface after washing, and determine the cleanliness through the formation of water droplets. When the surface is very clean, the particle water drops will evenly wet the pavement layer on the surface, and the shape around the condensed water film is regular circle after being dry.

⑤ exhale against the surface of the dry cleaning target. When the water vapor condenses on the surface, it will form a turbid fog spot. The fog spot generated when the surface is clean is even; otherwise, it is uneven. When the appearance is very flat and smooth, the fog spots will disappear in a short time.

Cleaning many hardware workpieces, a better cleaning method is ultrasonic cleaning, can clean a large number of workpieces, and the cleaning effect is strong. Many factories and workshops are using ultrasonic cleaning machine for cleaning work, which can save a lot of labor cost and time and energy cost.

Article origin: Jiangmen hardware processing and manufacturinghttp://www.xh-mingyuan.com

-

12-14

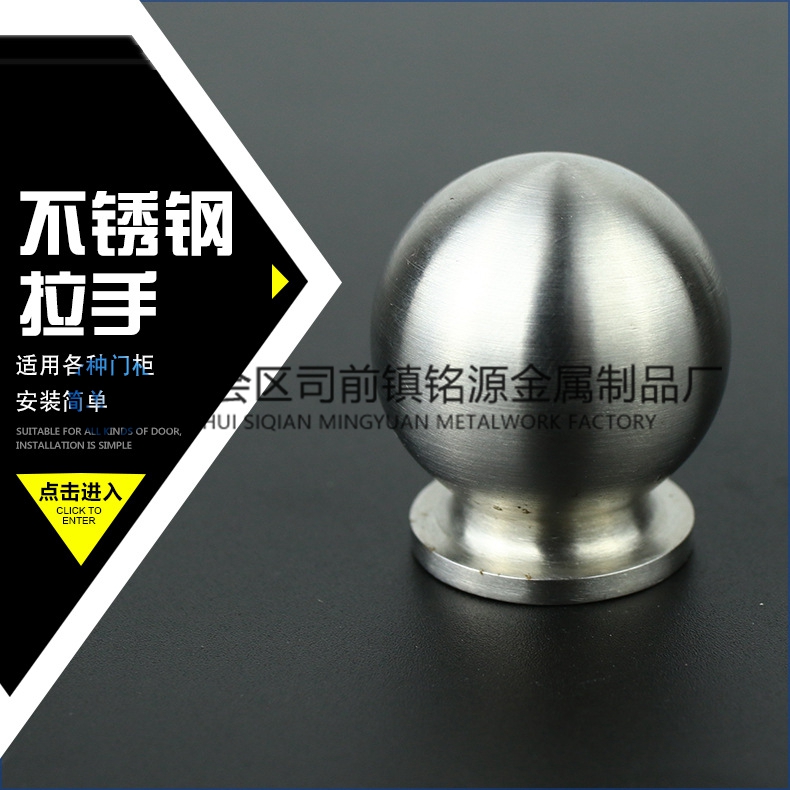

What drawing effects does Jiangmen stainless steel factory have

There are many kinds of stainless steel wire drawing processing, the more common are straight lines and random lines, others are corrugated and threaded.1. Stainless steel wire drawing straight lines: this kind of wire drawing treatment is very common, and the processing is relatively simple. The result of processing is that many straight lines are formed on the surface. This kind of processing ca

-

12-14

What factors affect stainless steel rusting

1. Content of alloy elements.Generally speaking, steel containing 10.5% chromium is not easy to rust. The higher the content of chromium and nickel, the better the corrosion resistance. For example, the content of nickel in 304 material is 8-10%, and the content of chromium is 18-20%. Such stainless steel will not rust in general.2. The training process of the manufacturer will also affect the cor